MIL-C-13864B(EA)

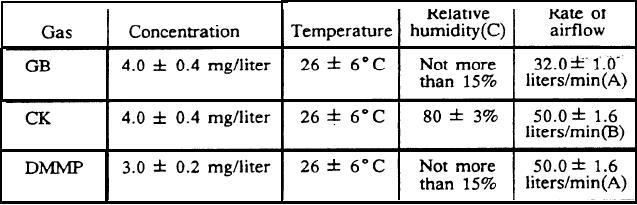

TABLE V. Conditions for gas life testing

(A) Constant flow

(B) Intermittent flow

The gas life shaII be reported to the nearest 0.1 minute.

4.4.6.10 Charcoal dust emission. The dust emission shall be measured using the Q261

Canister Shaker Tester (Drawing 136-45-842). The Q261 shall be used to accelerate dust

emission in the canister. While the canister is being shaken, the dust shall be collected on

a high efficiency filter which collects particles 0.3 microns or larger by drawing air through

the canister at a constant flow rate of 50 + 5 liters/minute for 20 minutes. The dust

emission shall be determined gravimetrically, using a balance sensitive to 0.1 mg. The

collection filter shall be either moisture-proof or shall be desiccated to ensure minimal

moisture absorption.

4.4.6.11 Rough handling. Canisters shall be rough handled using the Q113 Rough Han-

dling Apparatus (Drawing 26-1 9-51). The rough handling machine shall only be operated

with four unit packed canisters for not less than 15 minutes.

4.4.7 Packaging tests.

4.4.7.1 Unit pack container leakage. The unit pack container shall be tested in accor-

dance with method 5009.3 of FED. TEST METHOD STD. NO. 101 using the hot water or

vacuum chamber technique.

4.4.7.2 Unit pack container tear strip. The key shall be attached to the tear strip

tongue of the unit pack can and rotated in a clockwise direction around the circumference

of the can. When test is conducted using an empty can, structural integrity of the tear strip

.

area shall be maintained during opening using a lid or other means.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business