MIL --- PRF --- 51483A(EA)

or equipment to the Government for review and approval prior to use. Requirements and veri-

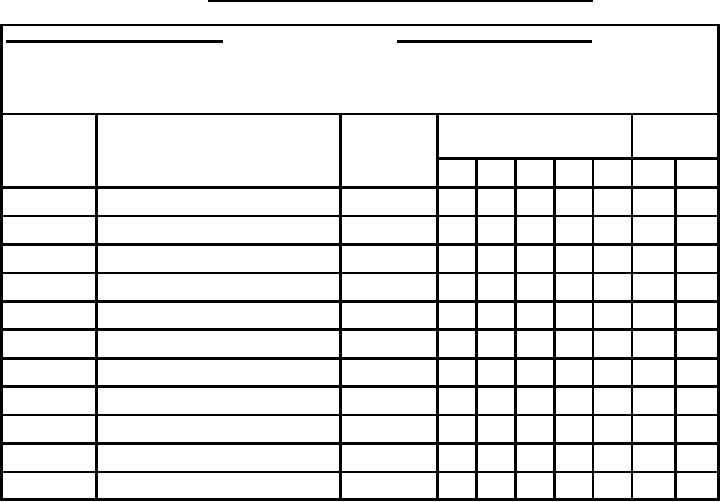

fication methods are cross referenced in Table II.

TABLE II. Requirement/verification cross --- reference matrix.

CLASS OF VERIFICATION

METHOD OF VERIFICATION

N/A--- Not Applicable

FA--- First Article

A--- Analysis

C--- Conformance

D --- Demonstration

E --- Examination

T --- Test

Verification

Verification Methods

Requirement

Verification

Class

Title

Paragraph

Paragraph

N/A

A

D

E

T

FA

C

3.2

Material

4.4.1

X

X

X

3.3

Performance

4.4.2

X

X

X

3.3.1

Edgeseal--- in --- filter performance

4.4.2.1

X

X

3.3.2

Edgeseal physical properties

4.4.2.2

X

3.3.2.a

Hardness

4.4.2.2.3

X

X

X

3.3.2.b

Tensile strength

4.4.2.2.4

X

X

X

3.3.2.c

Tear strength

4.4.2.2.5

X

X

X

3.3.2.d

Brittleness

4.4.2.2.6

X

X

X

3.3.2.e

Volatile loss

4.4.2.2.7

X

X

X

3.3.2.f

Viscosity

4.4.2.2.8

X

X

X

3.4

Instruction sheet

4.4.3

X

X

X

4.2 First article inspection.

4.2.1 Sample. The first article sample shall be submitted for inspection and approval in ac-

cordance with the terms of the contract.

4.2.1.1 Edgeseal material. The first article sample shall consist of 30 gallons of edgeseal

material manufactured using the same methods, materials, equipment, and processes as will be

used during regular production.

4.2.1.2 Inspection procedure. The first article edgeseal material shall be subjected to the

inspection procedures specified in Table II. A 1 --- quart (or more) specimen shall be taken from

the 30 gallon first article sample. From the one --- quart specimen, test slabs (small test speci-

mens) shall be prepared per 4.4.2.2.1. Those test slabs shall be tested in accordance with

4.4.2.2.3 through 4.4.2.2.7. In addition, a portion of the 1 --- quart specimen shall be taken for

viscosity test (4.4.2.2.8).

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business