MIL --- DTL --- 51170G(EA)

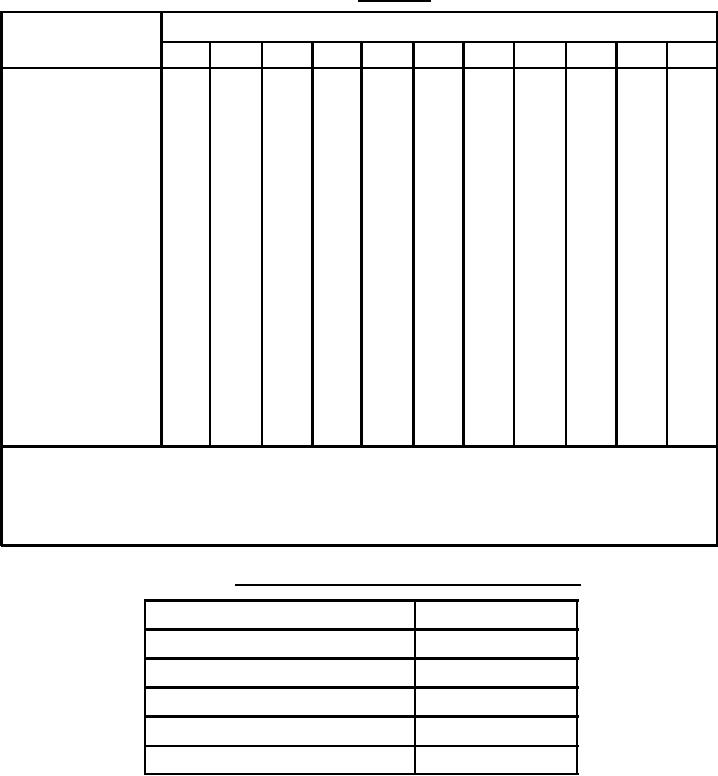

Table II. Sampling.

Inspection levels and sample sizes

Lot size

II

VIII

IX

X

XI

I

III

IV

V

VI

VII

3

*

*

*

*

2 to 8

*

*

*

*

5

2

3

*

8

*

*

9 to 15

*

*

*

13

5

2

*

20

3

16 to 25

*

8

*

*

*

13

5

3

5

*

8

*

20

26 to 50

*

*

32

13

5

5

*

20

6

51 to 90

50

8

*

*

32

13

7

5

*

7

50

12

20

91 to 150

*

125

32

13

11

6

*

10

151 to 280

50

19

*

20

125

32

20

13

7

11

50

21

315

47

281 to 500

*

125

48

29

16

9

15

75

27

47

315

501 to 1200

*

125

73

34

19

11

18

116

35

53

315

1201 to 3200

1250

125

73

42

23

13

116

22

38

68

315

3201 to 10000

1250

192

86

50

29

15

135

29

46

77

315

10001 to 35000

1250

294

108

60

35

15

170

29

56

96

490

35001 to 150000

1250

294

123

74

40

15

200

29

64

119

715

150001 to 500000

1250

345

156

90

40

15

244

29

64

143

715

500001 and over

1250

435

189

102

40

15

*Indicates one hundred percent inspection. If sample size exceeds lot size, perform

one hundred percent inspection.

Accept the lot represented on zero nonconforming characteristics and reject the lot

represented on one or more nonconforming characteristics for all inspection levels.

TABLE III. Sampling for leak integrity and marking tests.

Lot size

Sample sizes*

2 to 1200

13

1201 to 10000

20

10001 to 35000

29

35001 to 500000

34

500001 and over

42

*If sample size exceeds lot size, perform one hundred percent inspection.

Accept the lot on zero nonconforming characteristics and reject the lot

on one or more nonconforming characteristics.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business