MIL --- DTL --- 51400A(EA)

4.2 First article inspection.

4.2.1 Sample. The first article sample shall consist of 50 M1A1 bags and 21 square feet of

waterproof bag material (Drawing 5 --- 75 --- 13) manufactured using the same methods, materi-

als, equipment, and processes as will be used during regular production. The first article sample

shall be submitted for inspection and approval in accordance with the terms of the contract.

4.2.2 Inspection procedure.

4.2.2.1 For examination and test of waterproof bag material. The first article sample of bag

material shall be tested for all requirements of ASTM D 1593 and in accordance with the low

temperature resistance test (4.4.4).

4.2.2.2 For examination of bags. The sample bags shall be inspected for all requirements of

the drawings and this specification.

4.2.2.3 For test of bags. The first article sample bags shall be subjected to the tests specified

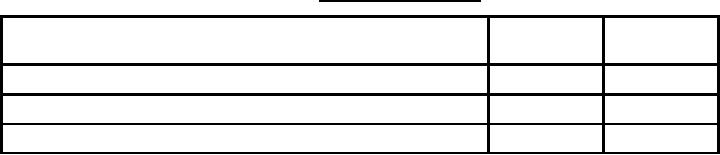

in table I.

TABLE I. First article bag tests.

Number of

Requirement

Inspection procedure

sample units paragraph

Leak integrity (4.4.1)

25*

3.3.1

Seam strength (4.4.2)**

25

3.3.2

Marking (4.4.3)

25*

3.3.3

*The same bags shall be used for the leak integrity and marking tests.

**Destructive test.

4.2.3 Acceptance criteria. If any first article sample item fails to comply with any of the ap-

plicable requirements, the first article sample shall be rejected.

4.3 Conformance inspection.

4.3.1 Lotting. A lot shall consist of the bags produced by one manufacturer, at one plant,

from the same materials, under the same manufacturing conditions, and at the same time. No

more than one lot of bag material shall be represented in any one lot of finished bags.

4.3.2 Sampling. Sampling shall be conducted in accordance with the classification of char-

acteristics in 4.3.5 and, when specified, tables II and III. Samples shall be selected at random.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business